Bookmark product

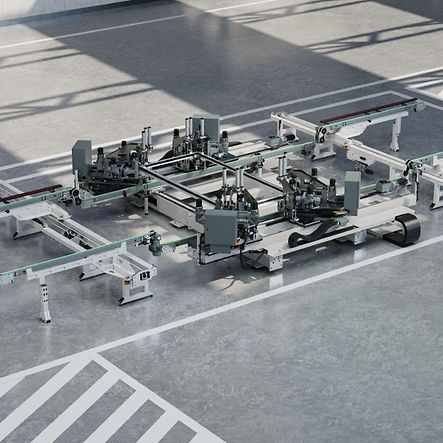

Schüco CC 800

Four at one go - faster than ever.

Our solution for the efficient installation of Schüco windows, doors and façades - the fully automatic four-head corner connector machine including automatic infeed and outfeed. Manually pre-assembled frames are accurately punched and transported out in high quality. The CC 800 lays the foundation for automated assembly and thus secures the future of the workshop. It punches a frame every 70 seconds, whether large or small. CC 800 - the new standard in frame assembly.

Fabrication benefits

- Fully autonomous punching process for a wide range of profile geometries

- High process speed: one frame every 70 seconds

- Integrated, fully automatic compensation of profile tolerances

- Profiles with a pre-retracted seal can also be punched without any problems

- Simple processing of profiles with plane offset without the use of special knives

- Flexible use in different workshop layouts, whether windows, doors or façade elements - particularly suitable for line production

- In two standard versions and special dimensions on request in small 2800x2400 for windows and doors or in large 3500x4500 for façade and sliding elements

- Preventive maintenance through logbook entries and pneumatic monitoring