Information about the reference project

Type of building: |

Office and Business |

Products: |

Doors, Façades |

Series: |

ADS 75 HD.HI |

Location: |

Ekaterinburg, Russia |

Completion: |

2020 |

Architects: |

Foster & Partners |

Specialist company: |

Mobil |

Picture credits: |

© Schüco International KG |

A shimmering metal façade

A shimmering metal façade

Headquarters of the Russian Copper Company

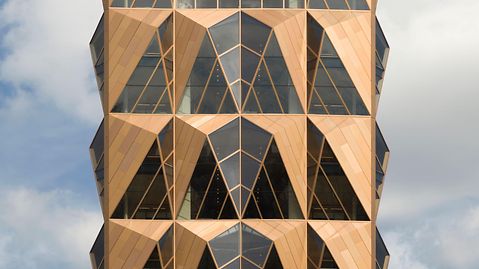

Whenever Yekaterinburg is mentioned, someone inevitably makes a reference to the execution of the Russian Imperial Romanov family in 1918. In 2003, the imposing Church on the Blood was built at the site of the shooting and quickly became a new landmark for the city with its golden domes. Just a few hundred metres south of this is the no less impressive, new headquarters of the Russian Copper Company, one of the world's top producers of copper. Designed by Foster + Partner, the 90 metre-high, 15-storey building offers a modern, open offce space consisting of individual modules each containing two offces stacked on top of one another. The main feature of the newbuild is the 12,500 m2 unitised façade with ist pyramid-shaped modules made from glass and copper-coloured steel, each measuring six metres wide and up to 12 metres tall. The size of the individual modules follows the double- level structure of the offce units.

Their crystalline structure consisting of four triangles reflects the company's corporate identity and the molecular composition of copper. However, it was primarily developed in view of the huge temperature fluctuations throughout the year, which sometimes sink to -40°C. In order to ensure optimum lighting and climate control in the interior, only two of the four triangles are made from glass, with copper-coloured steel being used for the others. An eye-catching grid of individual »pyramids« has therefore been created, the sides of which provide sun shading to shield the high summer sun, while the low winter sun can still warm the building. Priedemann Facade Experts architectural practice was involved during the concept phase, in order to translate the strict geometric specifications into a feasible parametric design. »One of the biggest challenges was the requirement to use local resources as far as possible, along with a local company to build the façade,« explains project manager Thomas Eschenbach. For the entire shell, 250 units were used in total with 50 different variations and each weighing around ten tonnes, and these all needed to be calculated individually. »The limited load-bearing capacity of the crane used means that we had to restrict the weight of the pre-installed units to seven tonnes,« explains Thomas Eschenbach. The copper-coloured stainless steel sheets and the internal aluminium cassettes could only be installed on the building site. Despite all these challenges, the project was completed on time in September 2020.

Source: Profile magazine, issue 25

Inspiration from the reference project