Schüco Search

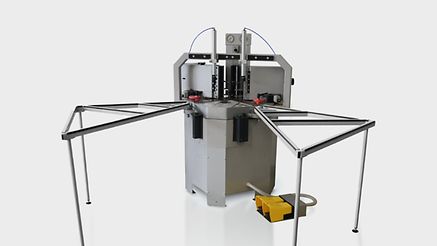

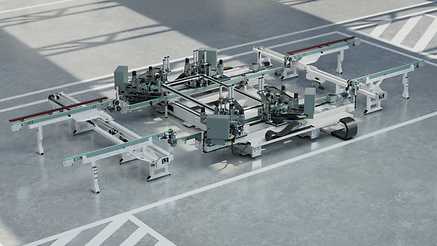

Corner crimping machines

Corner crimping machines: Installation made easy and efficient

With fabrication machinery, we support you with all tasks in the fabrication process for windows, doors, façades and special profiles. Like the corner crimping machines, our innovative solutions always have the same aim: to optimise your window construction workflow. Our corner crimping machines connect metal profiles effectively and ensure a long-lasting, secure construction.

This offers a number of benefits for your fabrication process:

• Fast window assembly while maintaining a high level of quality

• Time saved with each individual window assembly

• Low consumption of resources

• Significant cost reduction

My Workplace

Don’t have an user account yet?

Many benefits as a registered user:

- Work material (e.g. tender specifications, CAD data, catalogues)

- Software & Tools

- Note content

- Direct contact to Schüco