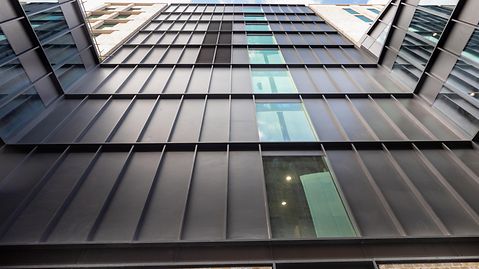

Architectural collaboration rejuvenates vibrant London development

Norton Folgate is an eclectic mixed-use development on Blossom Street, located near the iconic Spitalfields Market and Liverpool Street Station in London. The £180 million project involved extensive refurbishment of ten existing buildings, as well as eight new builds across six plots. The construction was a collaborative effort between multiple architects, façade engineer Eckersley O’Callaghan, specialist contractor Lindner Prater Ltd, and Skanska as the main contractor.

Location: London

Completion: 2023

Architect: AHMM

Façade engineer: Eckersley O’Callaghan

Specialist contractor: Lindner Prater Ltd

Main Contractor: Skanska

Photo credits: James Thompson UK Construction Photography

Products: USC 65, FWS 60, FWS 50, ADS 70 HI, ASE 60, ASE 80 HI, AWS 70 HI, AWS 75.SI+, ASS 70 FD, ADS 80 FR 30, FW 50 BF

With the diversity of the project, each plot presented unique challenges. The development features new commercial office buildings, refurbished office spaces and residential units, offering a blend of retail, hospitality, and public spaces. Allford Hall Monaghan Morris (AHMM) designed the masterplan in partnership with Stanton Williams, Morris + Company, DSDHA, and East.

The scheme harmoniously integrates modern designs with the existing architectural landscape, adopting a building-by-building approach to the retained structures, focusing on sensitive restoration and remodelling, as well as façade retention. For a sense of cohesion among the varied buildings, the architectural practices chose brick as the primary façade material across the entire scheme, however each practice adopted different types of brick, emphasising the character of the individual buildings.

Schüco partner, Lindner Prater, was tasked with the manufacture and installation of a range of Schüco façade and glazing systems for various plots.

“As the appointed specialist subcontractor for the glazing, cladding, and roofing packages, we worked closely with Skanska to ensure the seamless integration of Schüco systems,” explains Shane Blackett, Head of Procurement and Supply Chain at Lindner Prater.

“Our works encompassed a wide array of façade elements utilising Schüco glazing systems, unitised curtain walling, stick curtain walling, windows, single- and double- swing doors, sliding doors and bi-folding doors along with extensive rainscreen cladding.”

Early engagement

Working closely with Lindner Prater, Schüco became involved in the project from the pre-planning stage in 2014. Such early involvement allowed Schüco to provide guidance on façade systems that would meet the commercial brief, as well as key aesthetic demands, and the relevant building standards.

During this phase, Schüco presented its proposed façade solution to the project team and the client.

“The presentation ran through the USC unitised systems, which included eight different profile and gasket dies, as well as interface details with the aluminium cladding, and the installation process itself,” explains Schüco National Specification Manager Stephen Newell.

A key challenge the team were able to solve in the early design stages was ensuring that glass replacement was possible considering the large panel sizes, availability of fixing points, and location of the aluminium baguettes. Newell commented, “By engaging early on with the third-party supplier we were able to spot any potential issues that may have impacted on design, installation and cost.”

Meeting the brief

Reflecting on the project, Newell says, “Early collaboration combined with high levels of quality control ensured that the finished façade met all the requirements of the original 2014 brief.”

Lindner Prater’s long-standing relationship with Schüco and practical understanding of its products allowed for a smooth installation phase despite the challenges posed by the development’s busy location with limited on-site space. Situated in the bustling centre of London, between the City of London and Tower Hamlets, the project implemented off-site fabrication and just-in-time delivery to help mitigate this issue.

Linder Prater’s in-house fabrication facility ensured precision manufacturing and quality control resulting in products fabricated to the highest standard. The façade design included prefabricated elements which reduced installation time by around 50% and minimised labour requirements by approximately 75% when compared to traditional construction methods. This approach also significantly reduced carbon emissions by reducing the quantity of deliveries.

Sustainability was a key focus of the project which aimed to achieve net zero carbon and which has obtained BREEAM Excellent status. By utilising Schüco products, such as high-performance glazing systems, the project maximises natural daylight penetration while effectively managing solar gain, reducing the need for artificial lighting and cooling systems.

Norton Folgate exemplifies what it means to achieve a balance between historical preservation, modern construction, and meeting sustainability goals, through innovative solutions and collaboration.

Photos from the Excellence Awards 2024.

Norton Folgate

Photo credits: James Thompson UK Construction Photography

- Work material (e.g. tender specifications, BIM objects, CAD data, catalogues)

- Note content

- Direct contact to Schüco