With this material class, partner companies can meet DGNB certification requirements (quality level 4), lower their carbon footprint and take advantage of a non-fossil raw material basis. In PVC production, crude oil is replaced by tall oil, which is a by-product of paper production. It is a renewable, non-fossil raw material from pine trees that does not compete with the food chain. Compared to primary PVC made from crude oil, PVC made from tall oil saves up to 90 percent* CO₂e in the manufacturing process.

Bio-attributed PVC is integrated into the existing supply chains and production processes and can therefore also be individually combined with the BALANCED PVC or RECYCLED PVC material classes.

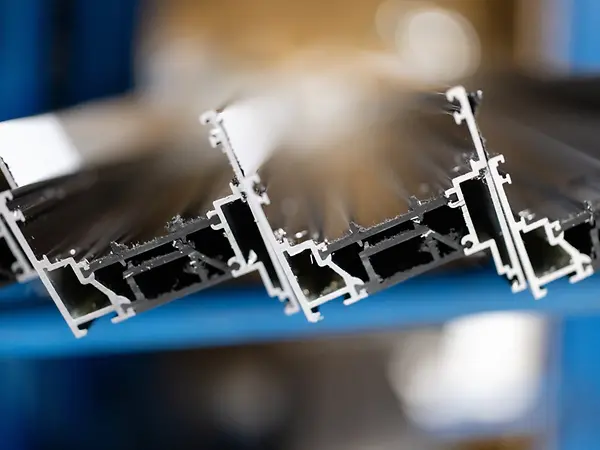

The process is RSB and ISCC PLUS certified, which means that the raw material can be traced along the entire supply chain from the paper producer to the company's own production facility in Weißenfels, which is verified annually by means of an external certification process. BIO-ATTRIBUTED PVC is available for all Schüco PVC-U systems.

*Compared to the manufacturing process of primary PVC from the same manufacturer